Compact 80 Boiler - right sided Fuel Feed

HDG10195046 / 10195046

Ring us for more information about the product

| Electrical Consumption | |

|---|---|

| Electrical Phase | Single phase |

| Fuel Type | |

| Fuel Type | Wood pellet |

| kW Power | |

| kW power output | 80 kW |

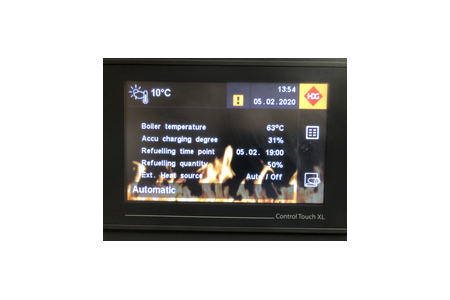

HDG Touch Controlled Boiler Controller

Latest generation Lambda controlled boiler 90% plus operational efficiency. The HDG Compatronic controls all processes required to maximise combustion

and fuel efficiency.

At start up fuel is incrementally fed on to the tipping grate, and automatically ignited, primary and secondary air is precisely added, ensuring that the fire is quickly established. Once the fire has become established, the controller changes from ignition mode to Lambda control, the controller optimises combustion and emission levels by using information provided by the Lambda sensor. The Lambda sensor continuously samples the flue gas. Information gathered from this analysis allows precise primary and secondary air actuator adjustments, this guarantees low fuel consumption and ensures that maximised annual efficiencies are achieved.

Automatic cleaning of the heat exchanger is a process that maintains efficiency and cleanliness. Any products of combustion removed from the heat exchange surfaces are extracted with the ash. Automatic ash removal promotes the fully automated ethos, ash that would normally remain in two containers within the boiler is screw fed into two convenient, simply removed wheeled containers.

Loading the accumulator is also precisely managed; one three way mixing valve and 3 PT 1000 temperature sensors, one at the top of the accumulator, one middle one at the bottom, they operate in conjunction with one another to achieve this control.

When the boiler is first ignited water circulation is limited to the heat exchanger until the temperature has risen to 60°C, this is a precautionary measure to prevent corrosion within the boiler water jacket. At 60°C the mixing valve gradually starts to open, allowing hot water to leave the closed loop and to start heating the top

of the accumulator. Once the water at the bottom of the accumulator reaches its preset temperature the boiler switches off. The boiler is turned back on again when the water at the top of the accumulator decreases to 60°C.

This procedure ensures maximum access to the high grade energy and prevents unnecessary boiler cycling.

The Compatronic controller has a residual heat utilisation programme, when the temperature of the water within the accumulator falls 5°C below that of the water within the boiler, the pump is started and mixing valve opened. This process

unloads the heat that was remaining within the boiler and makes it available for use within the building to be heated.

Integrated component protection, during dormant periods (possibly summer). The component protection program is always operational, all electrical components are energised periodically, the Lambda sensor is heated, and the boiler is ventilated, pumps and mixing valves are energised. This process extends component life time and efficiency.

HDG fuel feeding systems

HDG ash disposal

- Ash removal integral 15 litre containers (standard)

- Ash removal automatic, 2 x 35 litre external containers with wheels (optional) or single large container

- Automatic functions

- Automatic ignition

- Automatic heat exchanger cleaning (maintains high efficiency)

- Automatic tipping grate (making the boiler less fuel sensitive)

- Integrated accumulator loading management

HDG construction

- The boiler is manufactured in left and right hand versions (facilitating simple placement)

- Boiler Body – heat exchanger: welded construction, tension rod reinforced 4-5 mm thick boiler plate

- Certified in accordance to the pressure equipment directive 97/23/EG boiler class 3 (the highest standard)

- RAL colours - Green (RAL 6011) Traffic grey (RAL 7043)

- Integral thermal heat discharge within the heat exchanger

- Secondary combustion chamber: Modular design, manufactured from cast refractory bricks

HDG Safety Features

- Extremely robust rotary sluice (maximum operational safety)

- Heat exchanger thermal discharge

- Chip – pellet feeder quenching

- Fuel over fill sensor

- Excess heat exchanger temperature protection. Electronic via the Touch Control and mechanical via wax filled manual reset thermostat

- Automatic reverse on feed and dosing motors

- Minimum oxygen level automatic lock out

HDG standards and approvals

- Type tested to EN 303-5

- The Compact 45/50 qualifies for the Renewable Heat Incentive emission limits for total particulate matter and oxides of nitrogen 30g/GJ particulate matter and 150g/GJ NOx

- Approved for use in smokeless zones

- Touch Control

Mid sized pellet and chip boilers, automatic feed systems, automatic de-ashing and ignition