What is biomass wood fuel?

Difference between wood biomass and fossil fuels.

Its the time scale.

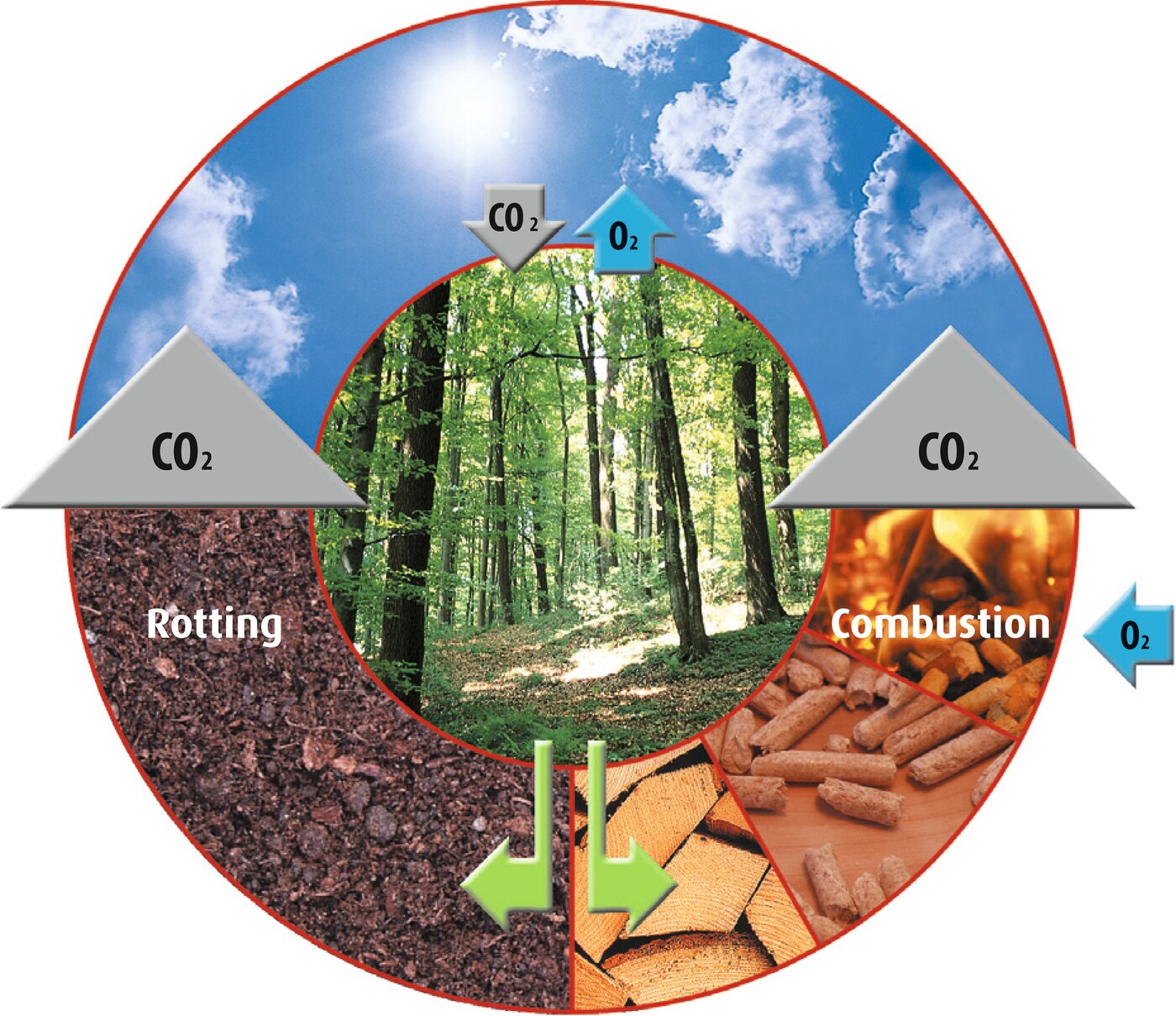

Biomass is any carbon based biological material derived from living or recently living organisms.

In the context of biomass for fuel this is often used to mean plant based material such as trees or crops.

We all know that trees help the planet, especially young trees. During their life, they absorb CO2 and give out oxygen. When they are cropped and used for fuel, they release the same amount of CO2 as they absorbed during their life and are therefore classed as being CO2 neutral. In contrast, burning fossil fuels such as coal, oil or gas, releases CO2 into the atmosphere that has been stored for many millions of years.

Wood burning appliances use fuel in the form of wood logs, wood pellets, wood chip or clean wood waste and there are products to burn each type.

Logs

Usually, the cheapest wood fuel, sourced locally commonly stacked and allowed to dry, processed into split 500mm lengths for quick and easy handling.

Wood Pellet

Pellets are compressed dried sawdust. Dense in nature and easy to move by automated processes.

Wood Chip

Chips are commonly virgin wood processed into a given chip size. Lighter than wood pellet though can also be mechanically moved to automate the burning process.

Wood can replace fossil fuels which will help the environment by reducing the amount of CO2 in the atmosphere.

WHAT ARE Wood Logs?

Wood log boilers typically burn virgin wood, which has been cut and processed into logs. Clean waste wood, such as carpentry offcuts, can also be suitable fuel. However, there are several important considerations when producing or purchasing wood, including proper storage and handling.

The most critical factor, whether you're buying or processing your logs, is moisture content. The wood must be dry, ideally with less than 20% moisture, and preferably under 15%.

Nature will dry wood if it is correctly stored

Wood will naturally dry in the UK, though the process may be slower in wetter northern regions. The drying time depends on the type of wood, how it has been processed, and how it is stored.

Typically, wood is ready to burn after about two years of being stored in proper conditions and split early in the summer of the intended use. By "two years," this generally means two full spring and summer seasons. However, if the wood is split and properly stored in its first winter, it may be ready for burning by the next winter, depending on the wood type.

Splitting wood is crucial because it exposes the internal surfaces, allowing moisture to escape more easily with the help of wind and sunlight. It also increases the surface area, speeding up the drying process.

The way it is stored is very important

To effectively dry wood, elevate it off the ground using a ventilated surface like a pallet. Cover the top with a waterproof material, preferably black to absorb heat from the sun, and position the stack in an open area where wind can maximise drying.

When it rains, roads become wet but quickly dry when exposed to sun and wind. However, in shaded or sheltered areas, it can take days for them to fully dry.

The same principle applies to wood storage. If you store wood in an enclosed space, like a closed garage, it will take much longer to dry. Instead, store your wood outside, elevated off the ground, and covered to protect it from most of the rain, while still allowing airflow to aid in the drying process.

Wood should be split

The density of the wood affects its drying time. Wood with a tighter grain structure takes longer to dry because moisture exits through the grain lines—natural tubes within the wood. When these tubes are smaller, it becomes more difficult for water to escape.

Hardwoods like oak have smaller moisture tubes, which slow the drying process, while softwoods such as pine have larger rings, allowing moisture to evaporate more quickly.

- Splitting wood speeds up the drying time.

- Splitting into smaller logs, wood dries even faster.

- Wood split for kindling dries very quickly.

Rule of Thumb

- 6” log in the round fresh, contains around approx 1 pint of water .

- Split it can be dry enough to burn in under 1 year if well stored.

The benefits

-

Simple to operate and ignite

-

Burns logs and clean wood waste

-

Correctly sized once or twice per day fuelling

-

Located in a boiler room simplifies cleaning and maintenance

-

Very high efficiency up to 92% depending on model

-

Wood logs can be stored locally to the boiler house

-

The boiler house can be located remotely to the property to be heated

-

Can be easily linked with an alternative heating source

The check list

-

Requires a dedicated boiler room capable of fitting the boiler and accumulator

-

Requires daily fuelling

-

Fuelling is undertaken by hand

-

Requires occasional ash removal

-

Requires annual maintenance by engineer

WHAT IS WOOD PELLET FUEL?

Wood pellets are small, typically 6mm in diameter and up to 15mm long, made from processed sawdust and wood chips. These materials are dried, heated, and compressed. Under high heat and pressure, lignin, the natural binding agent in wood, softens, allowing the wood fibers to be shaped and pressed into pellets.

Pellet-burning boilers offer a similar level of control to oil and gas appliances, making them an appealing option for many. Unlike logs, wood pellets can quickly regulate heat, allowing the system to be switched on or off as needed. An intelligent pellet transfer system moves the fuel from storage to the combustion chamber as required. A sensor controls the air supply, ensuring automatic ignition, and the system continuously adjusts heat output based on demand. Pellet-burning systems can be used to heat anything from a single room to an entire home or commercial space.

The benefits

-

Fully replace fossil fuelled boilers

-

Fully automatic control/feed systems

-

Automatic ignition and cleaning

-

Less bulky fuel and cleaner than log or wood chips

-

Boilers suitable for all size applications

-

Running costs are stable and reliable

-

Supports UK economy with pellets that are produced locally

The check list

-

Pellet quality is important for good operation

-

Higher installation cost compared to fossil fuel boilers

-

Requires dedicated boiler house and fuel store

-

Requires annual maintenance by engineer

-

Require occasional ash removal and inspection

WHAT IS WOOD CHIP FUEL?

Wood chips, made from both waste wood and sustainable virgin timber, are a completely natural fuel source. Wood chip biomass systems are best suited for larger-scale applications, particularly for those who can access a local wood supply or produce their own chips.

For optimal efficiency, wood chips need to be uniform in size and stored in a covered, well-ventilated area to allow for natural drying. Among automated biomass heating options, wood chips offer the most cost-effective solution.

The benefits

-

Can fully replace fossil fuelled boilers

-

Fully Automatic control/feed systems

-

Wood chips are lower cost than wood pellets

-

Installations can also be designed to burn wood pellets, sawdust and briquettes

-

Running costs are stable and reliable

-

Good for economy as source fuel can be grown and harvested locally

-

Several boilers can be grouped together for redundancy and peak heat demands

-

Remote boiler control over network or internet can be provided

-

Higher installation cost compared to fossil fuels

The check list

-

Requires larger fuel bunkers than wood pellets

-

Due to initial capital costs more suitable to larger domestic, commercial or industrial installs

-

Requires corrected sized graded fuel

-

Requires local maintenance and inspection

-

Requires annual maintenance by engineer

-

Requires occasional ash removal