What is a biomass boiler?

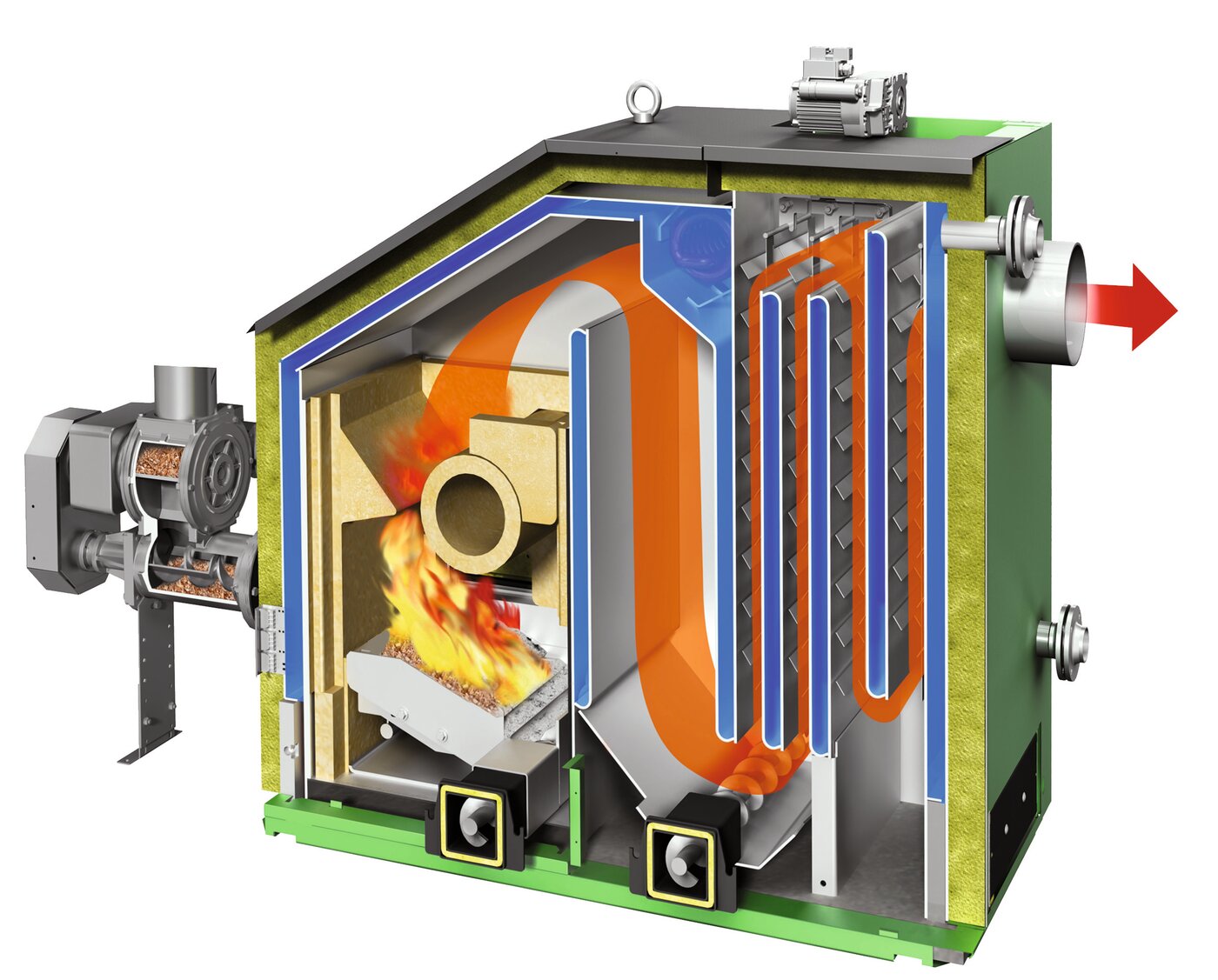

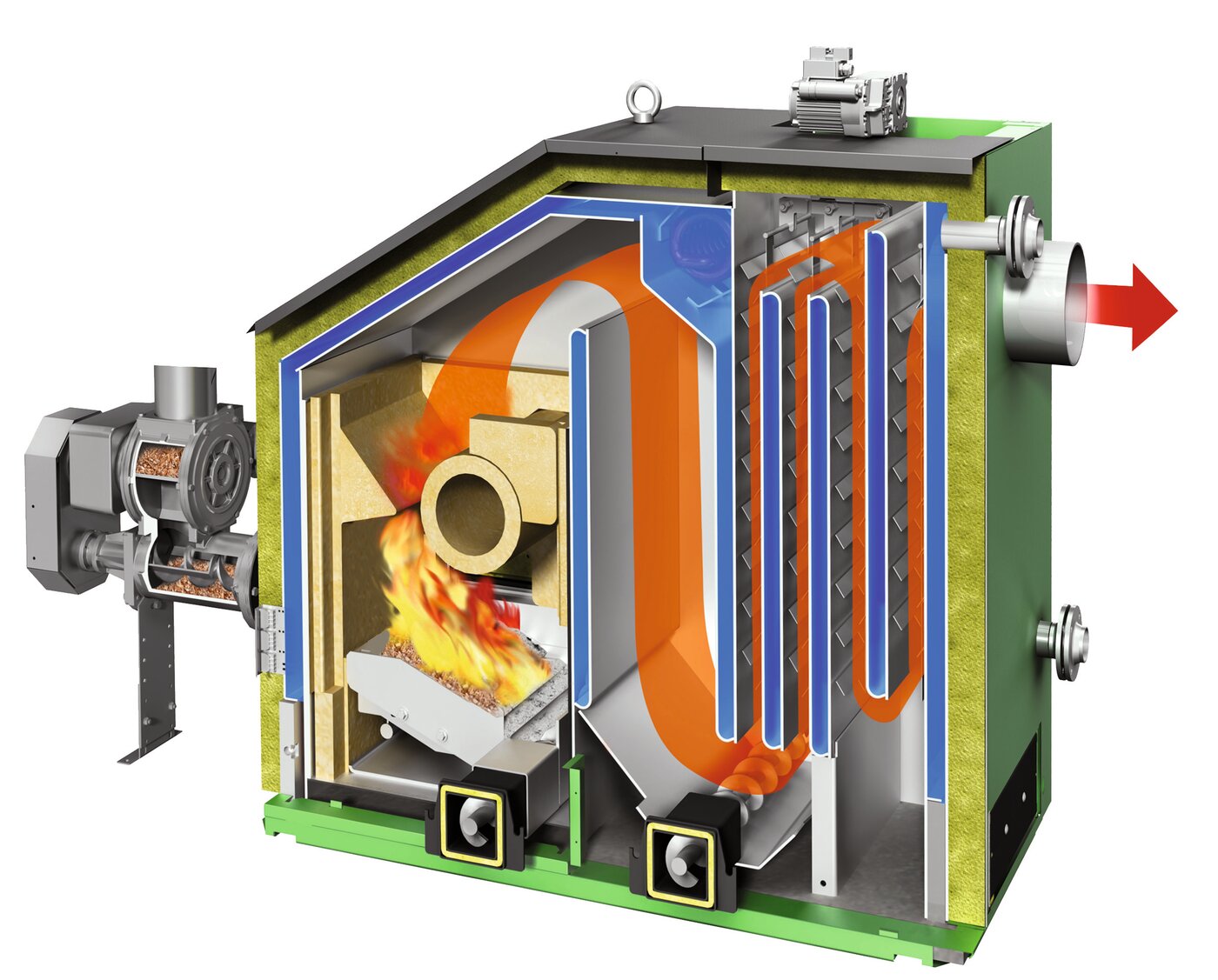

A wood biomass boiler is an appliance that burns biomass fuel through a process called gasification to heat large volumes of water in a tank surrounding the combustion chamber. While the concept may seem simple, achieving high efficiency requires several control systems and pumps to automatically regulate air for combustion and manage the flow of water around the boiler's water jacket.

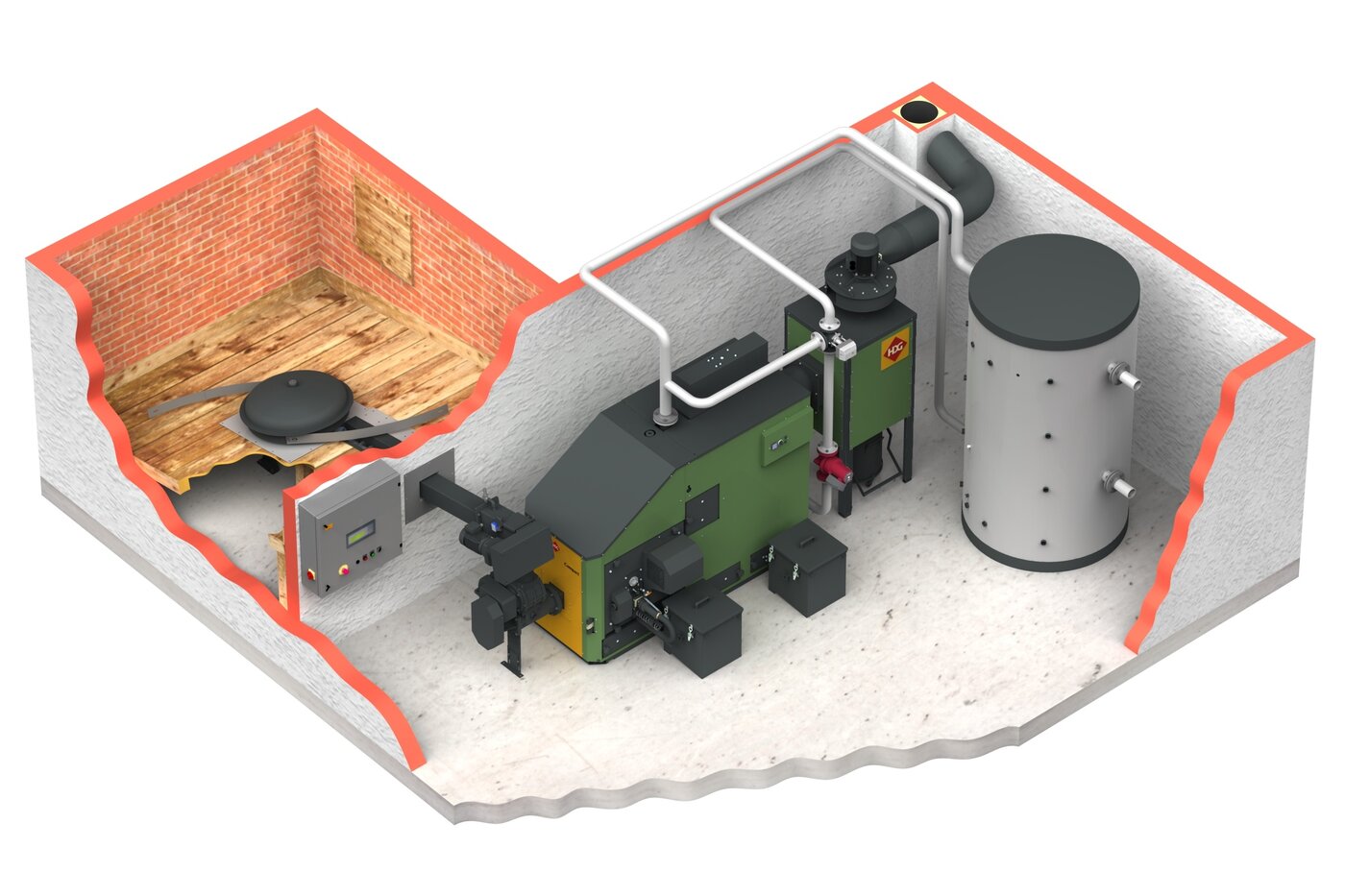

The heat generated is stored in a large, well-insulated container called an accumulator or buffer tank. This design allows the wood boiler to run for extended periods, reaching maximum efficiency by storing all the heat produced for later use. Similar to how a car achieves better fuel economy on long drives compared to short trips, the continuous operation of the biomass boiler ensures optimal performance and energy savings.

The wood burning appliances use fuel in the form of wood logs, wood pellets, wood chip or clean wood waste and there are products to burn each type.

WOOD LOG BOILERS

Modern log boilers offer clean and efficient heating, while utilizing one of the most cost-effective fuel sources. They are well-suited for domestic use and smaller commercial applications, such as country homes or small industrial buildings. However, for larger-scale applications, careful consideration is needed, as the process of splitting and manually loading the fuel can become labor-intensive and time-consuming.

Small domestic heating and light commercial |

HDG R SeriesThe R range of log boilers are ideally suited to the smaller domestic dwelling. Purpose designed for simple and easy operation. Most commonly used linked with a fossil fuel (oil or gas) boiler. Ideal entry level boiler for 2-3 bedroom property or highly insulated 3-4 bedroom house. 130 litre fuel chamber capacity (R20-30). HDG F SeriesAdvanced commercially constructed log boiler. HDG F Series 20,25,30Suitable for a well insulated 3-4 bedroom house with average hot water demand. Ideal as the primary energy source. HDG F Series 40-45-50Suitable for an averagely insulated 3-4 bedroom house or well insulated 4-6 bedroom property with above average hot water demand. Ideal as the primary energy source for medium commercial application such as offices, larger shop or industrial unit. 195 litre fuel chamber capacity. |

Larger domestic heating and commercial |

HDG EuroCommercially constructed log boiler designed for both domestic and commercial applications. Scale liner is an option, 220 litre fuel chamber capacity. Lambda controlled for excellent efficiency. As a guide the Euro 30- 40-50 range of boilers might suit: HDG Euro 30- 40Well insulated 3-4 bedroom house with average hot water demand. Ideal as the primary energy source. Small to medium commercial application such as small shop specialist business unit. HDG Euro 45-50Averagely insulated 3-4 bedroom house or well insulated 4-6 bedroom property with above average hot water demand. Ideal as the primary energy source. HDG TurbotecCommercially constructed log boiler for heavier load applications. Suitable for 1 meter logs with large fueling chamber. Lambda controlled for excellent efficiency: Suitable for larger country or urban properties. Large guest house or small hotel. |

Benefits of a log burning boiler;

- Simple to operate

- Burns logs and clean waste wood, resulting in very low heating costs

- Eligible for both the Domestic and Non-Domestic Renewable Heat Incentive Schemes

- Requires only once or twice a day fuelling (if sized correctly)

- Lambda controllers ensure high reallife efficiencies up to 93%

- Wood logs can be stored locally to the boiler house to reduce time and labour

- The boiler house can be located remotely to the property to be heated

- Can be easily linked with an alternative heating source

- Can have automatic ignition

- Can have on board fuel calculator which advises how much fuel to load into boiler

Nominal output and fuel chamber size

When choosing a log boiler, it’s essential to consider both its nominal output and fuel chamber size to ensure it meets your heating needs. The nominal output refers to the rate at which the energy stored in the wood is converted into heated water. To maintain adequate heating, the boiler's nominal output should match or exceed the property's heat loss rate, ensuring it can effectively keep up with demand.

Additionally, to minimize the need for frequent reloading and ignition, especially in average winter temperatures, the fuel chamber should be large enough to hold a sufficient amount of wood, allowing for once-daily loading and ignition.

Electronic combustion control

To burn wood efficiently, it's crucial to manage two stages of combustion: the burning of volatile gases and the burning of fixed carbon (charcoal). The initial release of wood gases occurs during gasification, where the wood is partially burned in the fueling chamber, releasing gas. This gas is then drawn into a separate combustion chamber, where it mixes with secondary air for complete combustion under optimal conditions.

To effectively control this two-stage burning process, modern boilers are equipped with intelligent combustion controllers, commonly known as Lambda sensors. These sensors are located in the flue of the boiler and continuously monitor flue gases. They adjust the primary and secondary air supply to ensure the boiler operates at maximum efficiency, leading to improved performance and reduced emissions.

Accumulators

During the combustion process, log boilers often produce more energy in the form of heated water than is immediately needed by the heating system. This excess heated water is transferred and stored in a highly insulated water tank known as an accumulator. The high insulation levels of these accumulators allow the energy to be stored for extended periods, ensuring it’s available for heating or hot water when required.

Options for Convenience

Several features can enhance the ease of using a log boiler:

-

Automatic Ignition Systems: These systems allow the boiler to be loaded with fuel at a convenient time. The boiler ignites automatically using an electrical ignition fan only when additional energy is needed by the heating system.

-

Fuel Loading Sensors: These sensors help users determine the appropriate amount of fuel to load into the boiler, taking into account outside temperature and forecasted energy needs. This ensures optimal performance and efficiency, making operation simpler and more efficient.

PELLET BOILERS FOR HEATING AND HOT WATER

Wood pellet boilers operate similarly to fossil fuel boilers. When heat is needed, they automatically ignite, feed fuel to the fire, and shut off as necessary. This automation makes them an excellent alternative for those seeking a cost-effective and environmentally friendly option compared to traditional oil, LPG, or electric heating, all while ensuring high comfort levels. They are suitable for a range of applications, from small domestic properties to large commercial facilities.

When choosing a wood pellet boiler, it’s important to consider several key factors:

-

Fuel Storage: Ensure you have adequate space for storing wood pellets, as this will impact your boiler’s efficiency and ease of use.

-

Energy Storage: Consider options for storing excess heat, such as an accumulator tank, to enhance efficiency and provide hot water on demand.

-

Control Systems: Look for advanced control systems that allow for precise temperature regulation and automated operation, ensuring optimal performance and convenience.

Benefits of a pellet burning boiler;

- Simple to operate

- Fully automatic control and feed systems

- Automatic ignition and cleaning

- Eligible for both the Domestic and Non-Domestic Renewable Heat Incentive Schemes

- High density wood pellet requires less storage space than other forms of biomass

- Significant fuel savings over oil, LPG and electricity

- Lambda controllers ensure high real-life efficiencies up to 93%

- Designed for long operational life

- Integrated weather compensation

Small domestic and light commercial |

K Series Mk2The K Series Mk2 range of pellet boilers are ideally suited to domestic properties or light commercial. Purpose designed for simple and easy operation both when fuelling with wood pellets or removing ash. As a guide the K Series Mk2 pellet boilers might suit: K10 Very well insulated modern house 2-3 bedrooms or more if of passive type construction. Older 1-2 bedroom property. K15 Very well insulated modern house 3-4 bedrooms or more if passive type construction. Older 2-3 bedroom property. K21 Well insulated 3-5 bedroom property. Poor insulated 2-3 bedroom. Small low energy commercial application such as high street shop. K26 Well insulated 4-6 bedroom house. Poor insulated 3-4 bedroom. Small low energy commercial, larger shop or small warehouse. Compact 25-50 rangeCommercially constructed pellet boiler for domestic applications As a guide the Compact 25-50 range of pellet boilers might suit: Compact 25 Well insulated 4-6 bedroom house with larger than average hot water demand and/or swimming pool. Small to medium commercial application. Compact 35 as Compact 55, though larger all round application. Compact 45 and 50 Medium to large country property or large urban house. Small school or rest home, manufacturing process with heat requirement or space heating.

|

Larger domestic , commercial & industrial |

Compact 65-80 rangeCommercially constructed pellet boiler designed for domestic and commercial applications. As a guide the Compact 65-80 range of pellet boilers are ideally suited for: Compact 65 Medium to large country property or large urban house. Small school, rest home, manufacturing process with heat requirement or space heating. Compact 80 Large country property or large urban house. Medium rural primary school, rest home, manufacturing process with heat requirement or space heating. Compact 100-200Commercially constructed pellet boiler for heavy load applications with continuous long operation periods or regular stop and start applications. Large country or urban houses. Medium to large hotels, rest homes and medical care. Large shop or showroom properties, such car, supermarket, shopping centres or out of town stores. Process applications such as wood fuel drying, food, animal, chicken production. M Series 175-400Industrially designed and built wood chip boiler for heavy work loads with nominal working hours of 4,000 hours per year. Larger shopping centres or showroom properties, such car, supermarket, shopping centres and out of town stores. District heating of housing estates, industrial complexes, etc. |

Pellet Storage

Pellet storage can either be incorporated locally within the boiler, or via a bulk pellet store that is either augered or vacuum transferred to the boiler. Pellets are available in pre-packed bags (normally 15 kg) for ease of handling and convenience, or bulk delivered for those looking for extended periods between refuelling and optimum buying price.

Buffer Tanks/Thermal Stores

Buffer tanks, or thermal stores, are crucial for the efficient operation of all biomass boilers The benefits gained from using an accumulator are substantial. Not only do they reduce fuel consumption they allow accumulated energy to be available immediately, there is no need to light the boiler. This reduces emissions and increases the life span of the boiler. In addition the buffer tank or thermal store allow multiple heat sources to be linked as well as offering your central heating system access to heated hot water

Combustion Control

As with all high efficiency biomass boilers, pellet boilers require clever electronic controllers to ensure the highest efficiencies possible. Typically, pellets are ignited in a combustion chamber where the volatile gases are driven off and gassified by adding secondary air. The controller ensures the precise mix of fuel, primary air, and secondary air at all stages of combustion.

Perfectly regulated with the HDG Control

The new HDG Control is the intelligent control centre for your entire heating system. Whether on the large touchscreen on the boiler or via the app: With HDG Control, you always have absolute control over your heating system.

- Control of combustion and output

- Control of external heat sources

- Integration of solar thermal systems, accumulators, heating circuits, mains pumps

- Domestic hot water preparation, etc.

- On request: Full web access and app for iOS and Android

SEE THE DEMO REMOTE HDG Control

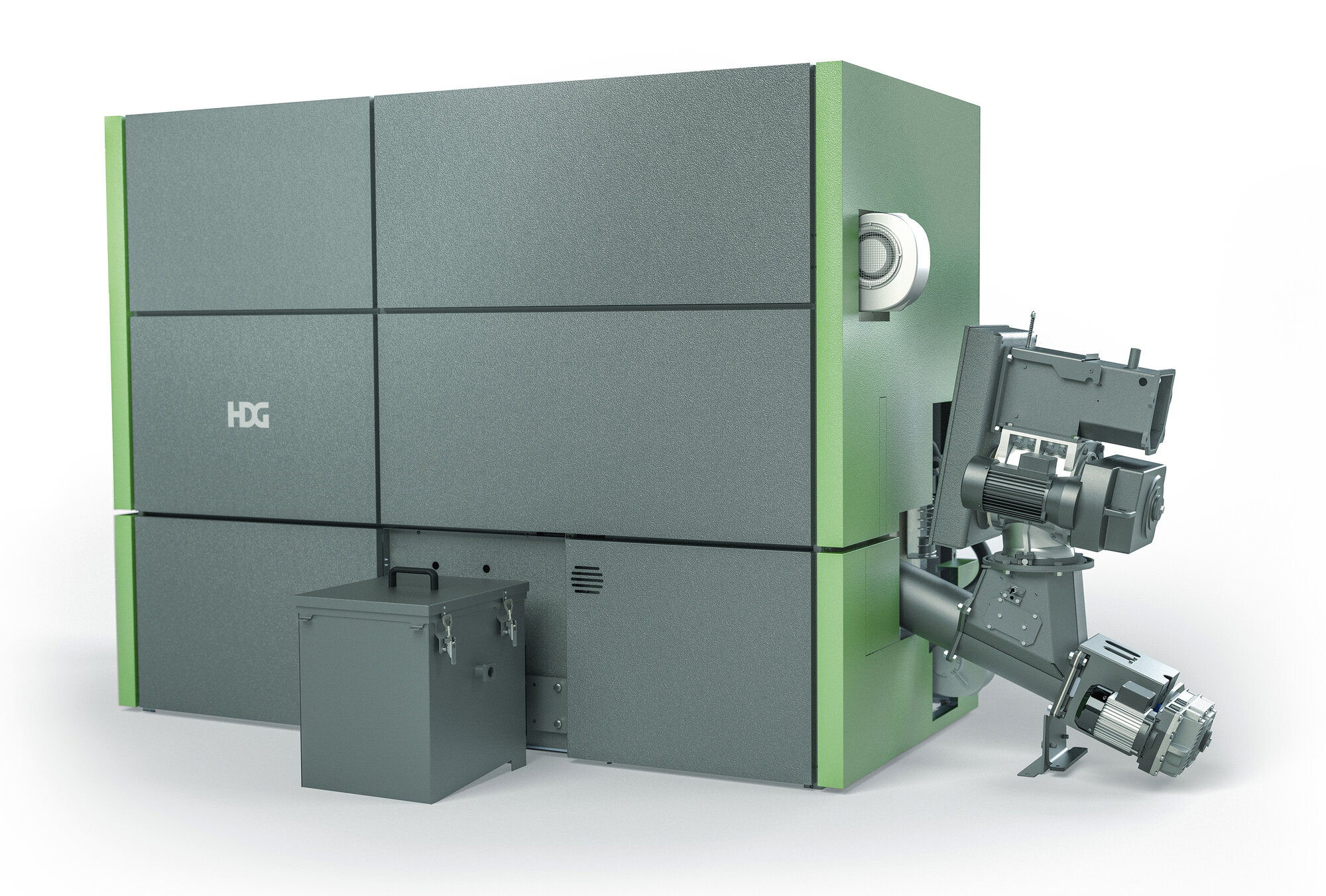

CHIP BOILERS FOR HEATING AND HOT WATER

Wood chip boilers operate similarly to fossil fuel boilers. When heat is needed, they automatically ignite, feed fuel to the fire, and shut off as required. Their automated functionality makes them an excellent alternative for those seeking a cost-effective and environmentally friendly option compared to traditional oil, LPG, or electric heating, while ensuring high comfort levels.

Wood chip boilers are typically more suitable for larger domestic and commercial applications, where the additional fuel savings can offset the slightly higher initial capital costs and the greater space and input required for fuel storage. Some models designed for wood chips are also capable of burning wood pellets, providing greater versatility in fuel options.

Benefits of a chip burning boiler;

- Fully automatic control and feed systems

- Automatic ignition and cleaning

- Option of automatic weather compensation

- Eligible for both the Domestic and Non- Domestic Renewable Heat Incentive Schemes

- Wood chips offer an automated heating solution at a lower cost than wood pellets

- Can utilise own/local woodland to provide fuel

- Significant fuel savings over oil, LPG and electricity

- Lambda controllers ensure high real-life efficiencies up to 93%

- Designed for long operational life

Smaller domestic properties and light commercial installations |

Compact 30-45-50-65-95 rangeCommercially engineered wood chip boiler sized for domestic and commercial applications. Compact 30-45Well insulated 4-6 bedroom house with larger than average hot water demand and/or swimming pool. Small to medium commercial application. Compact 45-50Medium to large country property or large urban house. Small school or rest home, manufacturing process with heat requirement or space heating. Compact 65Medium to large country property or large urban house. Small school, rest space heating. Compact 80-95Large country property or large urban house. Medium rural primary school, rest home, manufacturing process with heat requirement or space heating.

|

Larger domestic properties and commercial installations |

Compact 100-115-150-200 rangeCommercially constructed wood chip boiler for heavy load applications with continuous long operation periods or regular stop and start applications. As a guide the Compact 100-200 range of wood chip boilers might suit: Large country or urban houses. Medium to large hotels, rest homes and medical care. Process applications such as wood fuel drying, food, animal, chicken production. M Series 300-350-400-500 rangeIndustrially designed and built wood chip boiler for heavy work loads with nominal working hours of 4,000 hours per year. Larger shopping centres or showroom properties, car, supermarket, shopping centres and out of town stores. District heating of housing estates, industrial complexes. |

Combustion Control

Wood chip boilers require automatic combustion control to adjust to the varying nature of wood chip as a fuel. The most advanced and efficient boilers encompass a lambda sensor to adjust the primary and secondary air for the highest possible efficiencies. The controller ensures the precise mix of fuel, primary air, and secondary air at all stages of combustion to ensure efficiencies of up to 93%.

Fuel Storage

Wood chip boilers require larger fuel stores than the equivalent sized wood pellet system. Fuel stores should be sized so as to allow the boiler to run for a minimum of approximately 4 weeks in the coldest weather without the need to replenish the store. A number of methods can be used to fill the fuel store and are dependent upon individual sites and equipment available.

Perfectly regulated with the HDG Control

The new HDG Control is the intelligent control centre for your entire heating system. Whether on the large touchscreen on the boiler or via the app: With HDG Control, you always have absolute control over your heating system.

- Control of combustion and output

- Control of external heat sources

- Integration of solar thermal systems, accumulators, heating circuits, mains pumps

- Domestic hot water preparation, etc.

- On request: Full web access and app for iOS and Android