LRFC needed serious amounts of hot water to wash the mud away after matches, they also have two bars, offices, entrance hall and a large function room capable of hosting weddings and business conferences which require heating.

Ledbury Rugby football club are a busy sports club in Herefordshire and is heavily involved in the community providing youth teams and events for local children as well as managing two senior teams in the major leagues. As well as requiring serious amounts of hot water to wash the mud away after matches, they also have two bars, offices, an entrance hall and a large function room capable of hosting weddings and business conferences which require heating.

The hot water demand, after a match, to deliver enough hot water to clean sixty-plus players and the match officials is huge as well as managing to heat to the other parts of the establishment at the same time, something which the old heating systems failed to achieve. This system was split into two zones.

- Bar, meeting room, kitchen, toilets, office.

- Changing rooms and The Pavilion function room.

These two zones were a mish-mash of different heat supplies. Zone 1 had immersion heaters for the kitchen hot water, air heating for the entrance hall and a large gas boiler heating radiators in the bars. Zone 2 had two gas water heaters to supply hot water for showering and then a separate gas boiler for the radiator heating circuits and an air source heat pump.

The main issues were that in Zone 1;

- There was no easy-to-use time control with multiple time options to suit a varied operation.

- No use of weather-compensated heating to reduce energy input.

- No setback temperature option.

- No heating of male toilets linked to bar area use.

- No easy-to-use hot water time control to only heat hot water when required.

and Zone 2;

- No easy time control suitable for changing room use.

- Pavilion toilets are only heated when changing rooms are heated.

- No setback temperature option

- Hot water heated all the time 24/7.

Other general issues;

- Single hot water boiler with no backup.

- Single boiler for heating no backup

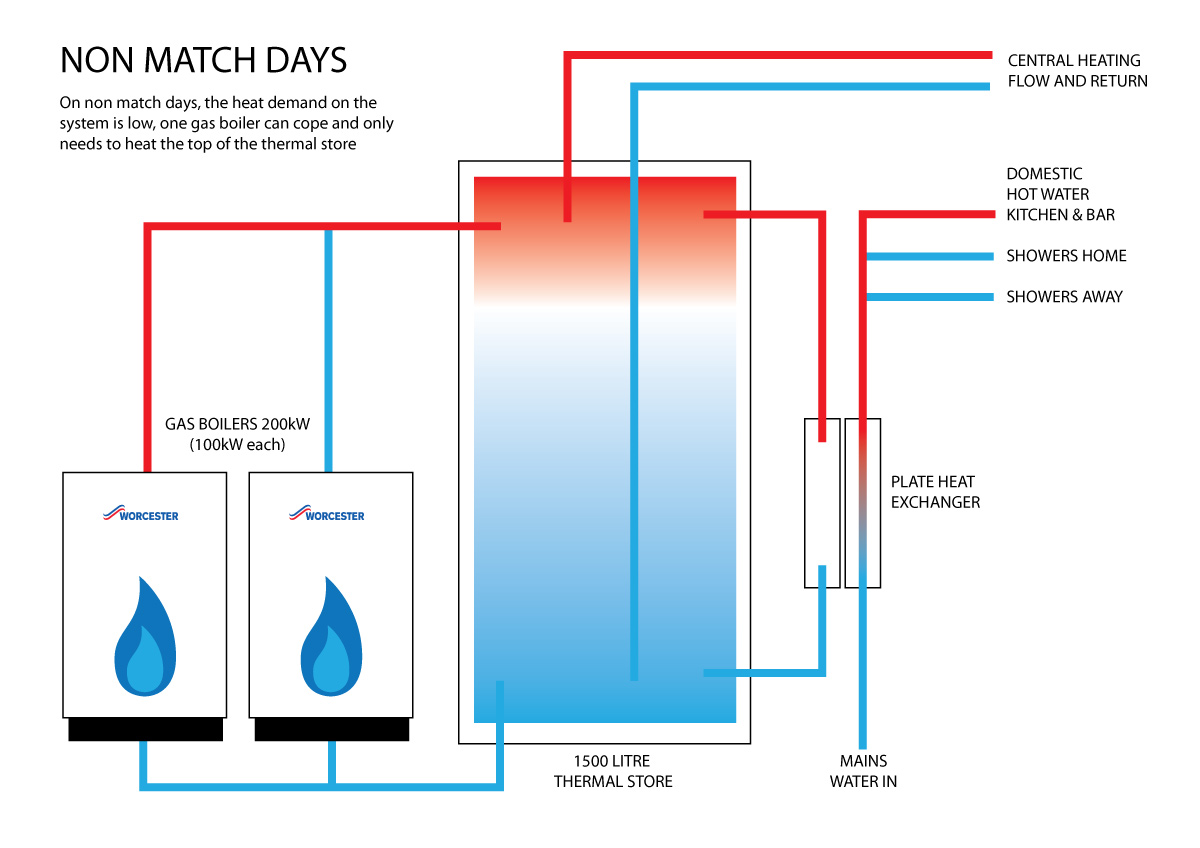

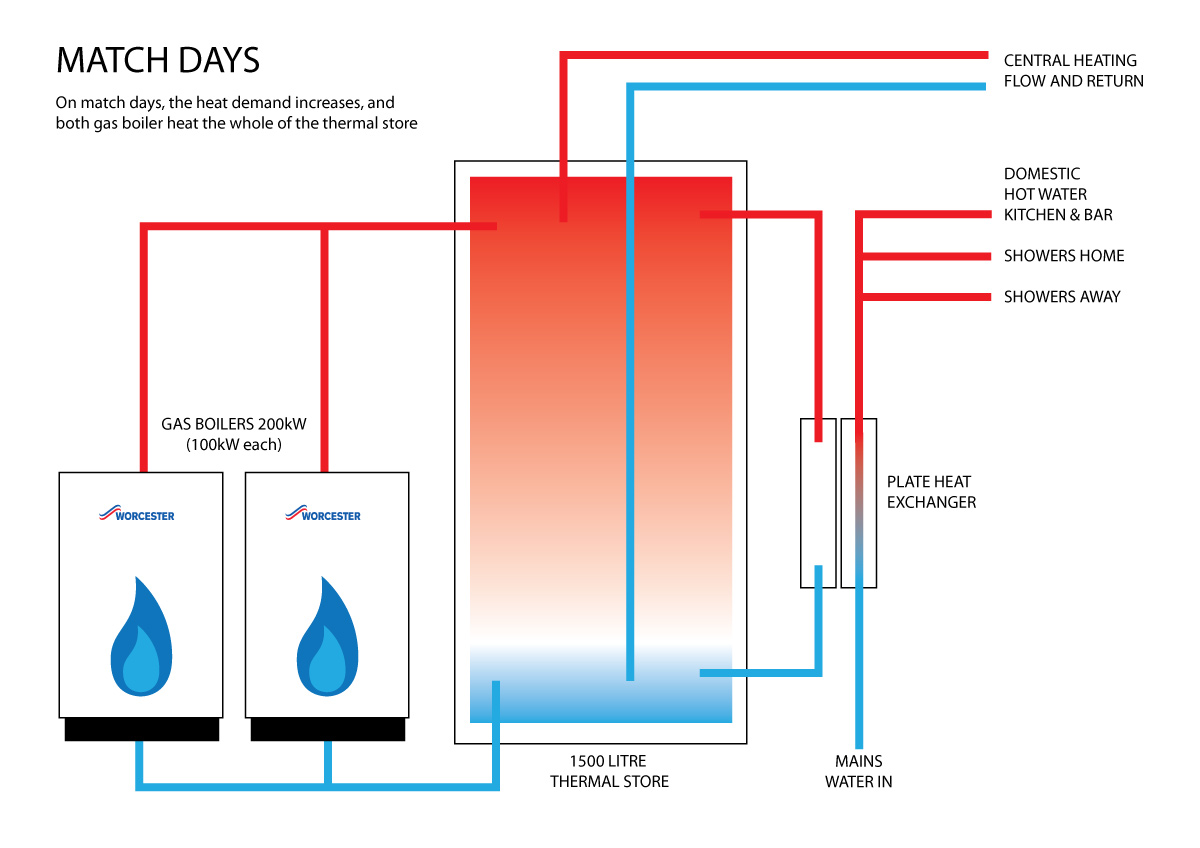

Careful calculations were needed to ensure that this peak demand of hot water for showering, could be met and was achieved by centralising heat production to one location, Using two boilers in a cascade, and linking two 100kW boilers to supply hot water and heating. A cascade also gives a backup capacity and allows demand to be quickly supplied as the boilers can operate from very low (one boiler on minimum) to maximum (both boilers on maximum).

There are also reduced servicing costs as there are only two modern boilers, instead of four old boilers and there are large energy efficiency savings over the old boilers as the replacements are condensing with very high efficiency.

There are four dedicated heating circuits;

- Bar/snug/reception/offices

- Pavilion function room

- Changing room 1 and 2

- Changing room 3 and 4

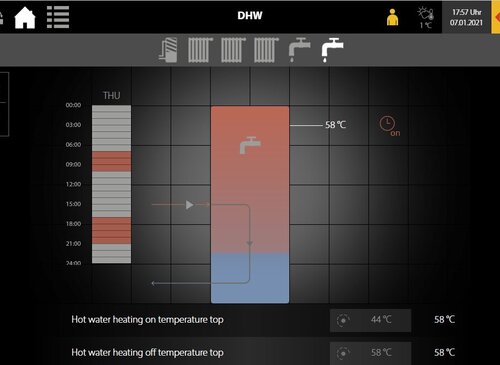

Hot water is supplied to the Bar and kitchen via a hot water cylinder, and the changing rooms have a large 1500-litre accumulator with high production hot water heat exchanger with a legionella kill program.

The hot water and the four individual heating circuits are controlled by a touchscreen controller and incorporate remote access through a web interface. The system is also fully weather-compensated for each heating circuit.

Weather-compensated control automatically adjusts the flow temperature to each heating circuit based on current weather conditions. IE the colder the outside temperatures, the higher the flow temperature to the heating circuit; the result is large energy savings. Weather-compensated heating also operates in two main ways, Day/living temperature and night/setback temperatures. This can be explained as an example of the new changing rooms.

The time control program for the winter season is selected and loaded. (a different program can be loaded for summer) The program has been pre-configured for times and days the changing room needs heating to day/living temperature. For example, on Tuesday evening 6.30 pm to 9 pm is rugby training and so we can set a room temperature of 22oC for these times. The other times are referred to as setbacks, and in the setback the temperature would be set to whatever is required, for instance 10oC, keeping the changing room aired and dry; plus, this offers frost protection.

This would apply to all four separate heating circuits which could operate at different times of the day, and different temperatures both day and night.

The benefits are large, and we estimate at least a 45-60% saving in gas usage with better overall heat distribution.

- By eliminating the patchwork of old equipment that had been added in an ad hoc fashion and completely redesigning the whole system with a focus on what was needed, a large saving in servicing (50% saving) and fuel costs (40-60% saving) were made whilst still providing more usable heat and hot water.