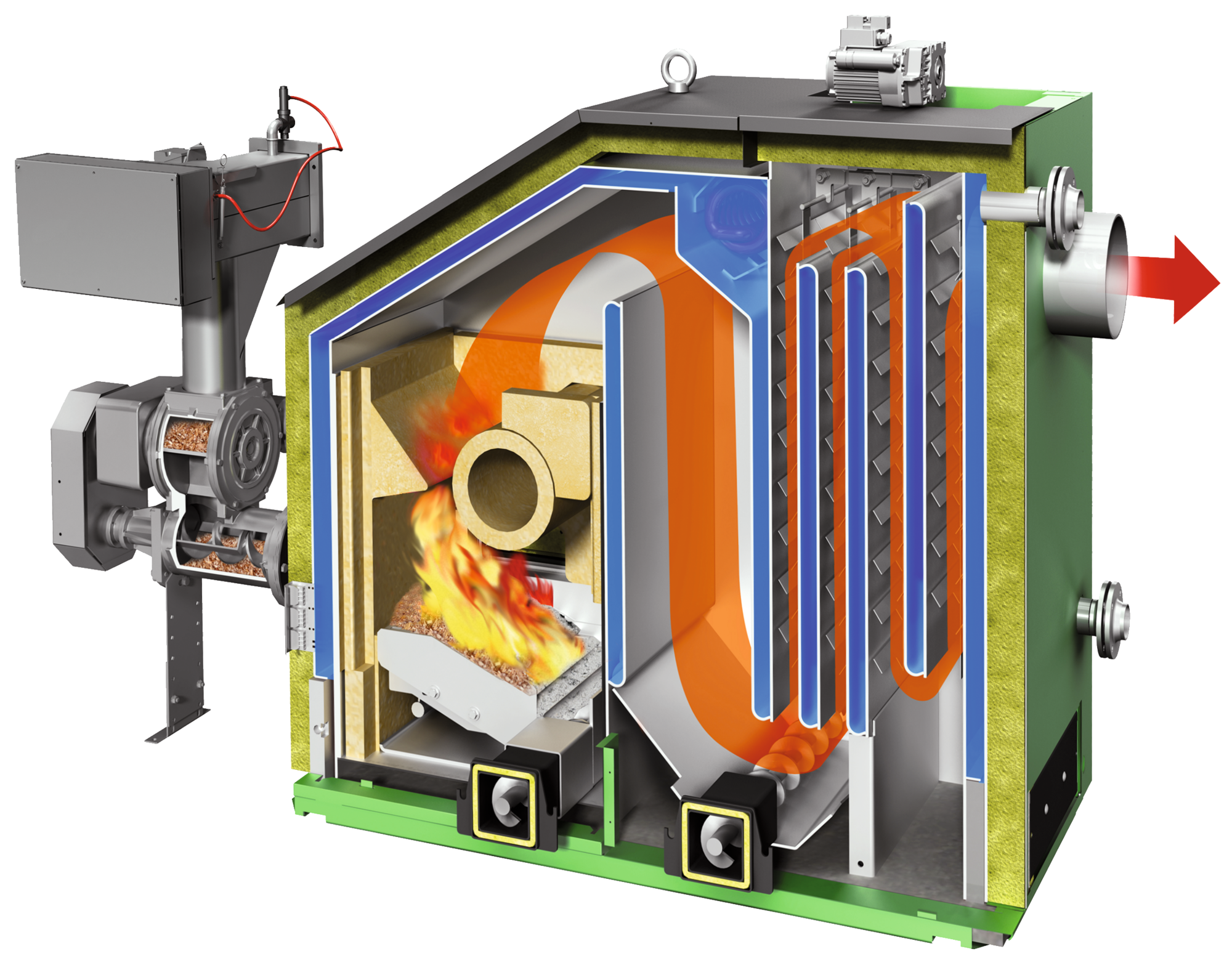

At the heart of the Compact 100 -200 and the HDG M series boiler lies the HDG step grate system. Step grates are usually associated with much larger boilers, because the cost of manufacturing this innovative moving grate solution would normally prevent its inclusion within a boiler of theses sizes.

However the deign team at HDG considered its advantages so important that a step grate has become a standard feature on all boilers 100kW and above. Step grates allow for greater fuel variability, by keeping the incandescent bed moving. This promotes complete fuel combustion & higher efficiency, reduced fuel sensitivity and linear output throughout the entire burn cycle.

However the deign team at HDG considered its advantages so important that a step grate has become a standard feature on all boilers 100kW and above. Step grates allow for greater fuel variability, by keeping the incandescent bed moving. This promotes complete fuel combustion & higher efficiency, reduced fuel sensitivity and linear output throughout the entire burn cycle.

The step grate is linked to the deashing augers so as the grate cleans the ash is removed.

Step grates allow for wetter fuel to be burnt in situations where wet wood chip although not ideal can be burnt at times of when sources of dry fuel may not be possible. The wet fuel moves down the grate drying as it moves until it burns.

The grate elements which slide forward and backwards based on present conditions in the HDG EPIS controller are constructed of special materials depending on the model size. For example, the C200 range the grates are constructed of Grade 310 Stainless steel.

Grade 310 is a carbon austenitic stainless steel, for high temperature applications such as furnace parts and heat treatment equipment. It is used at temperatures up to 1150°C in continuous service.