The aim of the redesign was to enhance the system's efficiency, improve heat delivery to the chicken sheds, and reduce unnecessary energy usage.

Project Overview

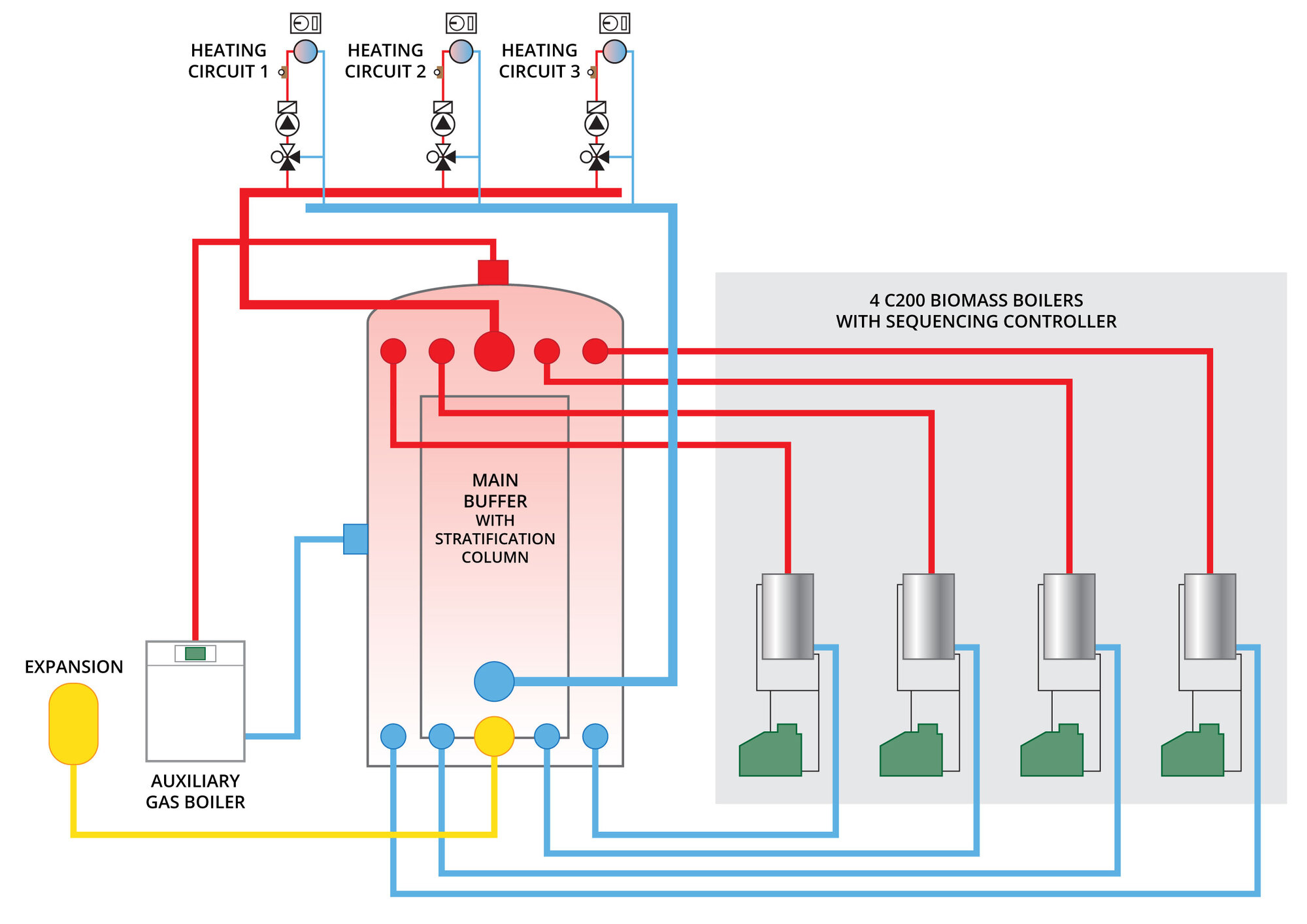

A poultry farm housing 220,000 chickens across six sheds required a re-design of its biomass heating system. The existing system relied on a manifold to distribute heat to three district heating circuits, powered by four HDG Compact 200kW biomass boilers. However, inefficiencies in the system led to excessive energy consumption, uneven heat distribution, and operational challenges.

The aim of the redesign was to enhance the system's efficiency, improve heat delivery to the chicken sheds, and reduce unnecessary energy and operational costs.

Challenges with the Old System

The old heating system faced several inefficiencies due to its design, particularly the use of a manifold as the primary heat distributor:

- High Flow Rates Through the Manifold

- The main manifold experienced excessive flow rates, causing heat delivery to the secondary district heating circuits to be inefficient.

- The secondary circuits were unable to return the cooled flow effectively to the system.

- Thermostat Issues

- The inability to return cold flow caused the thermostats in the sheds to continuously call for more heat, leading to a cycle of excessive heating demands.

- Overheating Boilers and Accumulator

- Hot water was being returned to the boilers before it could circulate through the secondary heating circuits, resulting in overheating of the boilers and the primary accumulator.

- Low Delta T

- The reduced temperature difference (delta T) across the system created a vicious cycle of increasing heat and high flow through the manifold, further impairing the secondary circuits’ ability to take or return heat.

Solution: System Redesign

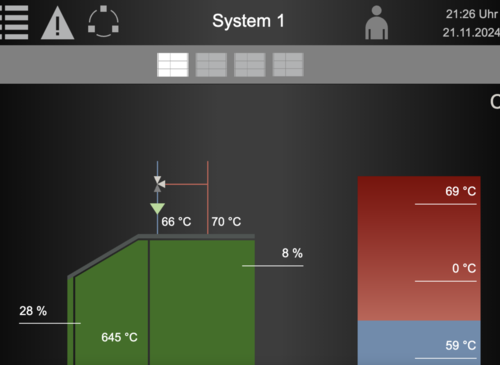

The solution involved removing the inefficient manifold and introducing a new accumulator with a stratification column. This redesign effectively optimized heat distribution, flow management, and energy efficiency.

- Removal of the Manifold

- The manifold was eliminated as the distributor, resolving the issue of excessive flow rates and poor return flow from secondary circuits.

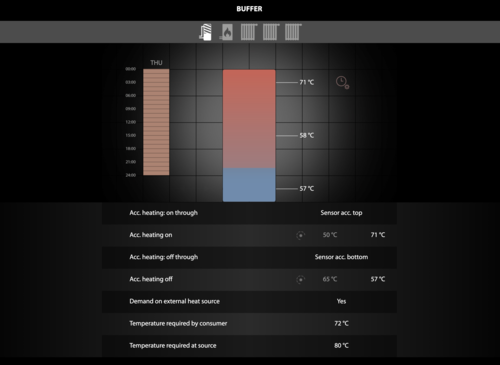

- New Stratified Accumulator

- A stratified accumulator was installed to replace the manifold.

- The stratification column ensured that the tank’s contents remained layered, preventing mixing and maintaining temperature differentials.

- Efficient Heat Flow Management

- Heat for the three district heating circuits was drawn from the top of the new accumulator.

- The return flow from the heating circuits entered the bottom of the accumulator, allowing cooled water to re-enter the boiler for reheating.

- Heated water was then delivered back to the top of the accumulator for redistribution.

- Energy-Efficient Pumps

- Energy-efficient pumps were installed to reduce electricity consumption, resulting in significant cost savings of up to £10,000 annually.

Results

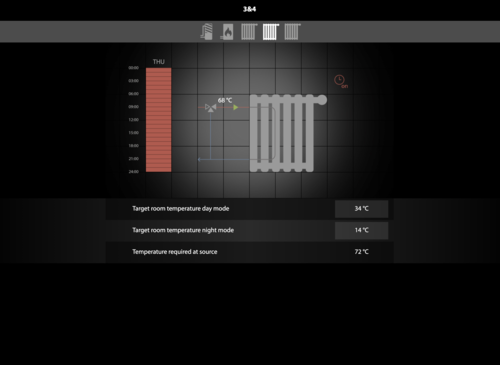

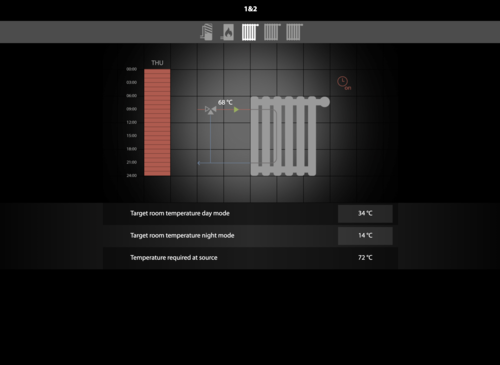

The redesigned system delivered significant improvements in efficiency, heat distribution, and operational performance:

- Enhanced Heat Distribution

- The stratified accumulator ensured a consistent supply of heat to the chicken sheds, meeting thermostat demands without overloading the boilers.

- Reduced Boiler Overheating

- By directing cooled water to the boiler and preventing hot water from cycling prematurely, the risk of boiler and accumulator overheating was eliminated.

- Optimized Energy Efficiency

- The new system maintained a high delta T, improving energy transfer and reducing energy consumption.

- Annual electricity savings from the energy-efficient pumps are estimated at up to £10,000.

- Significant Fuel Savings

- The redesigned system achieved over 25% fuel savings, equating to approximately £25,000 in annual cost reductions.

- Improved Food Conversion Ratio

- Better heat provision and distribution improved the chickens' food conversion ratio, leading to increased productivity and greater profit margins for the farm.

Conclusion

The re-design of the biomass heating system successfully addressed the inefficiencies of the old manifold-based system. By replacing the manifold with a stratified accumulator, incorporating energy-efficient pumps, and optimizing the overall system design, the farm experienced substantial financial and operational benefits.

This project highlights Zero Ridge’s commitment to delivering tailored, cost-effective, and sustainable heating solutions, supporting both energy efficiency and improved operational outcomes for clients.

- Annual electricity savings from the energy-efficient pumps are estimated at up to £10,000.

- The redesigned system achieved over 25% fuel savings, equating to approximately £25,000 in annual cost reductions

- Better heat provision and distribution improved the chickens' food conversion ratio, leading to increased productivity and greater profit margins for the farm