Accumulator & Buffers options, sizes and technical details.

Buffers, accumulators and thermal stores explained

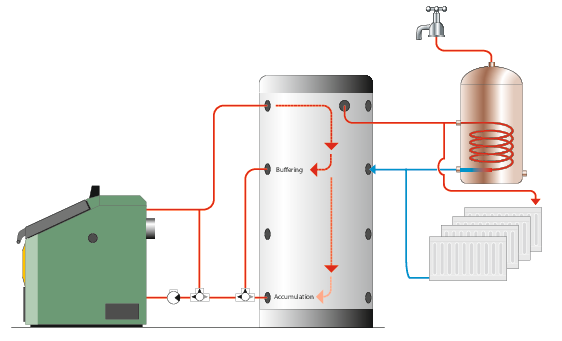

The biomass industry has several name conventions for process of storing heat energy in water. At Zeroridge the following system descriptions are used to define the type of heat storage, buffer, accumulator or thermal store, and assist with the system design and

project requirements.

A biomass boiler burning wood pellets, logs or wood chip needs time to operate. It needs time to introduce fuel and ignite it, time for the fire to establish before producing its full output and time to burn the remaining wood in the fuel chamber at the end of its cycle.

This differs from fossil fuel boilers which can quickly achieve their full output and switch off, biomass boilers need time to react and respond. Older generations of wood boilers do not have the ability to switch on, and off, because they were designed to be used in parts of the world where there are sustained periods of very cold weather. In such places having only full and partial load is possible because there is always a heat demand. In the UK where outside temperatures and weather conditions can change quickly boilers need to be able to adapt to different heating demands.

All automatic HDG boilers constantly monitor the amount of heat being stored in the buffer, ignite only when there is a need to produce heat and stop when the demand is met.

This greatly increases the overall annual efficiency, reduces fuel consumption, reduces environmental emissions, servicing costs and extends the boilers life. Manually fed log boilers require greatly increased human input because the fuel needs to be loaded by hand, even though the actual ignition can now be automatic. Poorly conceived installations can result in many trips to reload the boiler on colder days. A correctly sized log boiler and accumulator will allow the user, in most cases, to provide enough heat by lighting and loading the boiler once each day.

Accumulator

As the name suggests its main purpose is to accumulate energy. In this case the energy is heat energy from a log wood boiler. The function of the log boiler is to convert the energy stored in wood log to heated water.

To be able to do this cleanly and efficiently the combustion needs to be able to proceed in a controlled and steady fashion. A correctly sized accumulator will ensure that the boiler will be able to maintain a high temperature without needing to choke the fire causing smoke and tar, reducing the efficiency and life of the boiler.

The accumulated heat is then used on demand from the accumulator. In very cold weather the property may use this energy in a matter of hours, most of the winter over the course of 24 hours, and in the summer, because the accumulators are highly insulated, the heat will

be available for heating domestic water for a number of days. Accumulator designs come with stratification columns, and snorkels as standard for log boilers. Also available are additional stratification plates, solar coils and electric heating elements. Sizes range from 1500 litres to 10,000 litres and multiple accumulators can be connected in parallel.

Buffer

As the name suggests the vessel is used as a buffer of energy between the heat source and the heating system. Because automatic biomass boilers take more time to respond to a heating demand than a fossil fuel boiler, a buffer is used between the boiler and the heating system, when there

is a demand the heat being drawn from the buffer signals the biomass boiler to ignite and produce heat. The buffer also ensures that when the automatic biomass boiler is started it runs for an optimum length of time irrespective of the amount of heat being used by the building. The boiler then stops when the buffer is fully charged and waits for the heating system to use the energy produced, when it then repeats the cycle. This is done by sensing the water temperature, and because the buffer is highly insulated, during periods of light load it may not be required to fire again for a day or more. As a method of preventing the boiler

starting and stopping more often than necessary the buffer has a huge impact on the boiler efficiency, a reduction in wear and tear, reduced emissions and fuel consumption.

Buffer sizing is based on the output of the biomass boiler, but may be over-sized when being connected to large district heating systems to accommodate the volume of water in the system. Buffers are generally much smaller than the accumulators used with log boilers, and are of a similar construction with stratification columns, and snorkels as standard. Buffers are also available with additional stratification plates, domestic hot water coils, solar coils and electric heating elements. Sizes range from 1500 litres to 10,000 litres and multiple accumulators can be connected in parallel.

Probably the most poorly explained and confusing term is for a buffer/accumulator. These are generally best described as a small buffer undertaking many functions. These include some buffering and some accumulation, although their ability to do both is limited because they are generally small in size, normally 200 litres to 500 litres. They are used on small heating demands and to produce domestic hot water with either an internal coil or external heat exchanger. They are also used to integrate multiple primary sources such as wood stoves, fossil fuel boilers, heat pumps, solar thermal, and

electric heating. Although smaller they are of a similar construction to buffers and accumulators with options of domestic hot water coils, solar coils and electric heating elements.

- Stratification

- Multiple connection sizes & snorkels

- Stratification column

- Solar thermal options

- DHW coils

- Electric element options